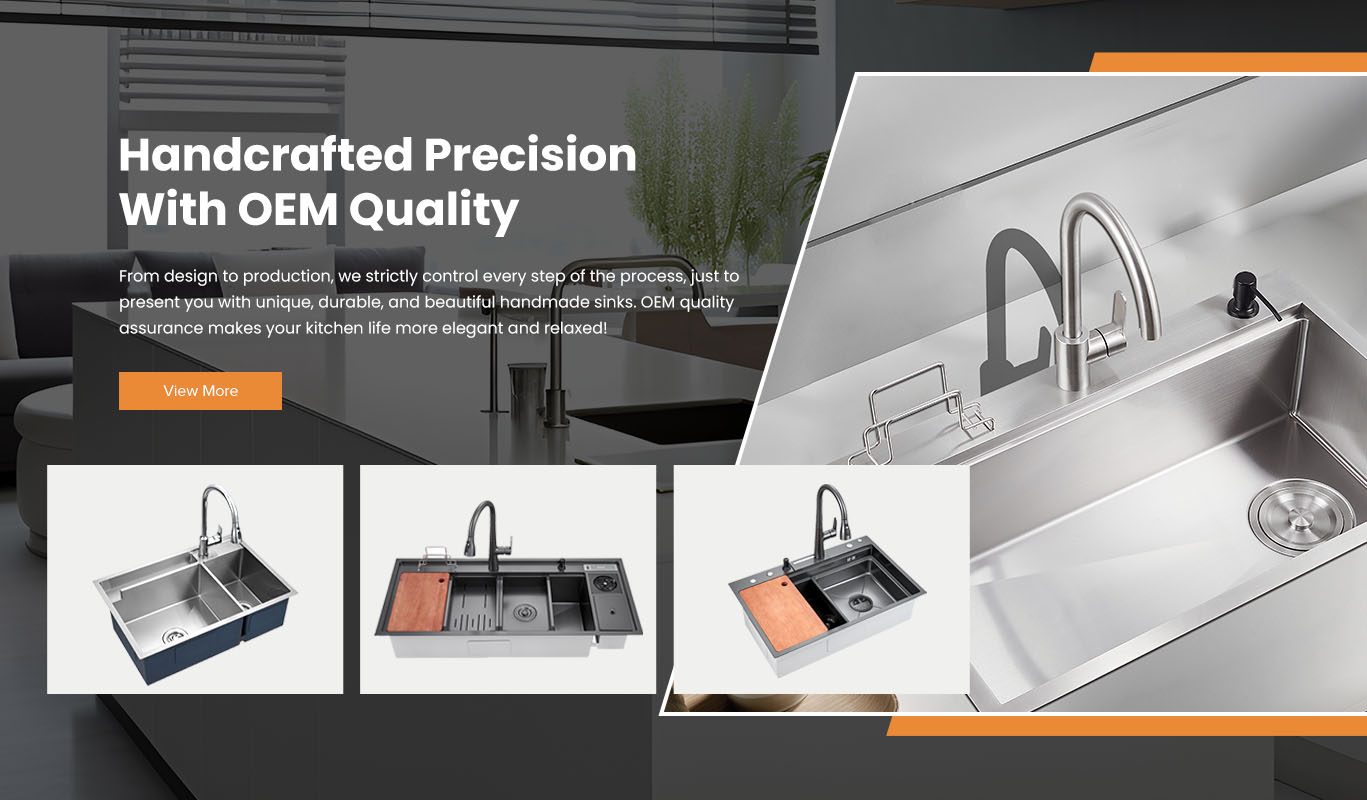

From a manufacturing and surface-engineering perspective, stainless steel sinks are finished with controlled grain patterns to balance scratch resistance and ease of maintenance. Shunhan Sink, as a manufacturer specializing in stainless steel kitchen sinks, produces sinks with consistent surface finishing that allows light scratches to be blended and polished effectively when proper methods are used.